An aerospace OEM wanted to replace its legacy paper-based workflows, including manuals and drawings, with a digital ecosystem.

Infosys implemented a digitization program at the aerospace enterprise for a sophisticated shop floor driven by digital technologies.

Key Challenges

- Paper-based manuals related to production and work instructions were scattered across systems

- Meeting appointments, jobs definition, dispatch and status updates required human interface

Ready to experience?

TALK TO EXPERTS

The Solution

Digitization of shop floor processes drives operational excellence

Infosys implemented a digitization program to transform operations on the shop floor.

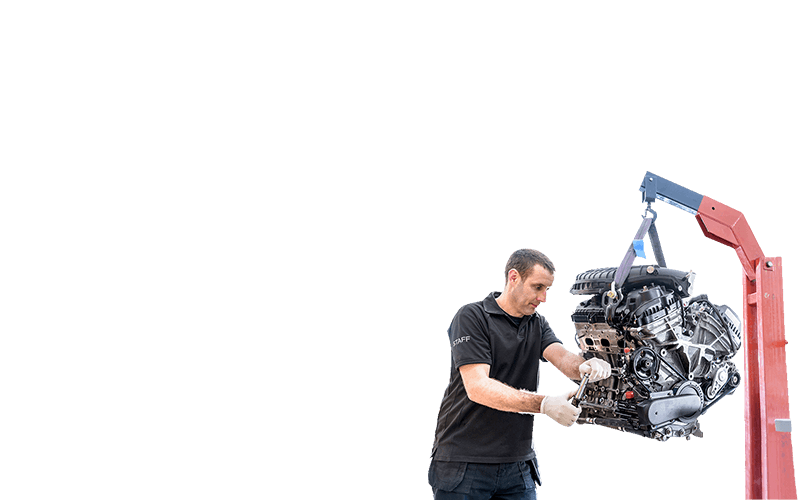

Our solution made digital work instructions, checklists and 3D drawings available across Enterprise Resource Planning (ERP), Product Lifecycle Management (PLM), and Quality Management Systems (QMS), enabling ready access to shop floor operators and supervisors.

Personnel on the shop floor receive instructions on their mobile devices, thereby accelerating time-to-market. Mobile checklists provide procedural updates, which helps maintain quality control. In addition, digital instructions reduce the complexity of logistical workflows.

Digitization enhances shop floor operations

- Integrated, paperless, digital shop floor environment

- Real-time visibility into production processes

- Minimal human intervention on the shop floor

Benefits

Infosys digitized the operational processes of the shop floor

Delivers real-time 3D drawings and visual work instructions

Staff receives instructions and production orders electronically, and shares real-time updates using mobile checklists